Before you buy dog grooming scissors it’s important to know how they work and how they are made. Scissors work with a lever system, but if you simply screw two pieces of metal together, they won’t cut. The blades of the scissors are turned lengthwise and the cutting edges are directed upwards so that an angle is created and the scissors can cut. Otherwise, the 2 pieces of metal would squeeze instead of cut.

The blades are bent towards each other to have a contact point along the length of the cutting edge. This curvature creates a pressure that is absorbed by a back pressure on the inside of the blade under the screw.

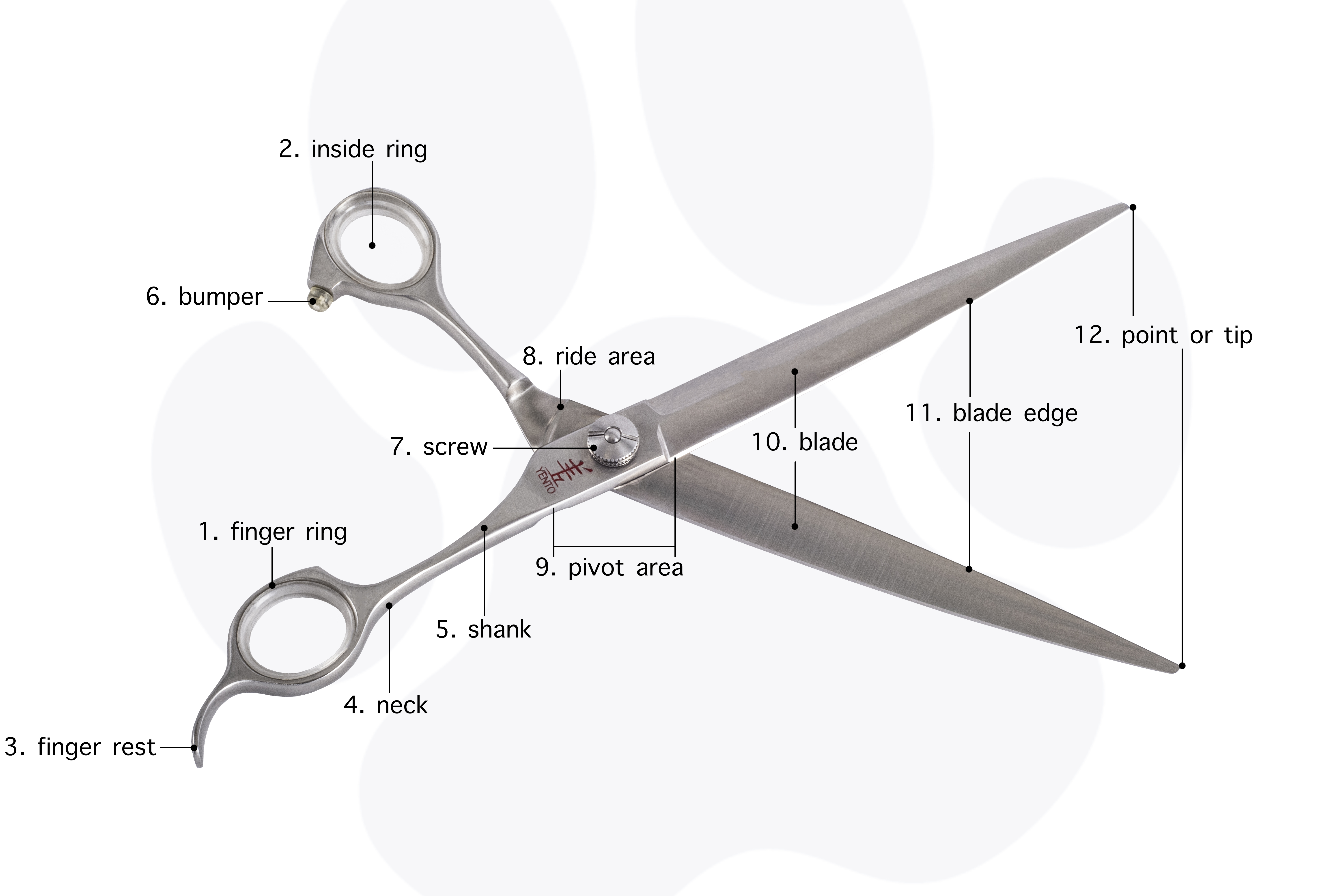

Dog grooming scissors have the following parts:

- Finger ring

- Inside ring

- Finger rest

- Neck

- Shank

- Bumper or silencer

- Screw

- Ride area

- Pivot area

- Blades

- Blade edge

- Points or tips

The difference between cast and forged grooming shears

Casting: in this production process they heat up the steel until it is liquid and pour the steel into a mold. There is, however, a disadvantage to this way: when the shears have cooled down, the molecules are separated in the steel and it is no longer so hard.

Forging: in this production process the metal is heated until the steel glows red. It is then forged and shaped by compression force. The blades can be made separately and then welded together with the handle. Here the steel remains at its hardest point.

Metal types for dog grooming scissors

In order to obtain good quality grooming scissors, one must of course make these from the best metals. Each pair of scissors is meticulously hand-made and undergoes many processes before the final result is achieved. Scissors are made of nickel-free, stainless steel and are deep-frozen (tempered) to guarantee maximum hardness. This process ensures that the metal is so hard that it can no longer bend and therefore the sharpened cornering stays sharp for longer.

Steel type 420: This stainless-steel alloy is one of the softest steels there is. This type contains negligible amounts of carbon and lots of chromium in the metal, which makes it very soft and resistant to rust. Scissors produced with the steel sharpen very easy because the metal is soft and as disadvantage you will have to sharpen more frequently. Scissors produced with this steel will be cheap to buy but be careful: they will cost more in the long run because of the extra sharpening that you will have to do.

Steel type 4034: This stainless steel (X46Cr13) with special Solingen forging is one of the most popular types of steel for producing grooming scissors. These shears have a long-lasting cutting edge after a heat treatment. The most famous steel is produced in Solingen. The steel type 4034 has a very good balance between hardness and keeping the cutting edge sharp. This steel is used to make the famous cutters from Solingen Germany.

Steel type 440A: This stainless-steel alloy is one of the most popular steels for producing dog grooming scissors. If the heat treatment is well done the shears can hold their edge very well. The most famous steel is produced in Japan. The 440-type steel has a very good balance between toughness, rust resistance, keeping the sharp edge and cost.

Steel type 440C: Is similar to the 420A but the steel mixture contains more carbon and because of the carbon the factory can temper the shears with a higher hardness which results in stronger scissors.

Steel type V-7: This V-7 steel material has been developed in collaboration with Utsumi and the steel manufacturer. V1 steel material is widely used for shears like the ones Utsumi makes. Adding tungsten steel to V-1 steel material for anti-friction and adding vanadium makes the blade stronger.

Steel type V7M: V-7m steel is also an original steel which was developed in collaboration with Utsumi and a steel manufacturer especially for producing curved shears. If the steel is strained, hard steel will break when making and folding the curved scissors. However, using softer steel does not help the performance so this problem needs to be solved using hard steel V-7 and covering it with elastic steel SU304. This makes for a double steel: the soft steel forms the shape of the curved blade and hard steel helps to get the sharp edge. The method of making one blade from too different types of steel material (soft and hard) has been used in making swords and is a very advanced processed technology.

Steel type V10: This stainless-steel alloy is harder because it contains more cobalt, the name stands for V Gold 10 (gold meaning quality). This type of metal has the ability to have a sharper edge on the blade and is proven to keep the edge longer. Downsides are the price and the fact that the factory has difficulties to produce scissors in this steel because it’s so hard to work with.

Steel type ATS314: ATS-134 stainless-steel alloy is produced by Hitachi steel company in Japan. The edge holding ability of their steel is one of the best because you can create very light grooming scissors with a very fine blade and still have an extremely sharp edge that will keep for a very long time. Downsides are again the price and the difficulty of producing scissors in this type of steel.

Steel type Damascus: Damascus stainless steel alloy is like the Ferrari of all steels for producing shears, this steel was used for producing the legendary Samurai sword. You can recognize this steel immediately because by a distinctive pattern of banding and mottling like flowing water. Many people also say it looks like a wood pattern. Damascus steel is made of multiple layers of metal which are fused together to create a single piece. Damascus is not the hardest steel but has an advantage for scissors, as the combination of metals creates micro-serrations on the edge that hold the hairs in place while cutting. Damascus also tends to stay sharper for longer, which is a definite advantage. The production process for the Damascus steel and the scissors in this quality is very difficult and therefore also has the highest cost.

Scissor blade types for dog grooming scissors

It is important to know the difference between the different types of scissor blades before buying grooming scissors. Hollow-ground scissors have hollowed-in blades. This means that only the cutting edges make contact with each other and therefore do not make any noise during cutting. Good quality scissors are often made this way.

Convex blade: Grooming scissors with convex blades have an extremely sharp edge and certainly do not require physical strength to cut through thick coats. This is the strongest finish and can handle more advanced cutting techniques without any problem, for example already sliding cutting. These scissors require more care due to their sharp edge. These blades are ground at 45° to 50°. This method is more difficult to make than many others, so scissors with a convex blade are usually more expensive than others.

Beveled edge blade: This technique is one of the oldest, least expensive and quickest technologies to sharpen a pair of scissors. The scissors have an angled edge that is ground between 40° and 47°.

Semi convex blade: Semi convex is a grinding technique between convex and beveled edge. The edge is not cut as edgy as the beveled edge but is more angular than a convex blade. This has the advantage that you can use your scissors longer without having them sharpened. The disadvantage is that the scissors do not have such a sharp edge anymore and therefore you can experience problems in thick coats that you have to exert pressure to cut through.

Serrated edge or Corrugated beveled edge blade: A serrated edge blade has very fine grooves on the cutting edge. These ensure that the hairs are better grasped when cutting and thick coats are easier to cut. This technique can be applied to either one or both blades. Grooming scissors with these types of blades make more noise during cutting.

Scissor handle types for dog grooming scissors

There are many types of handles, depending on the maker, the application, the appearance of the grooming scissors, etc. The most common are: crane grip, opposing grip, and offset grip.

Crane grip handle: this type is the standard and the most common nowadays. One finger ring is an extension of the cutting blades and is longer than the thumb ring. This is the most ergonomic handle and has great advantages for the body. The thumb ring is shorter than the other finger ring. The crane grip allows you to lower your elbow in a more relaxed position. This design also reduces the stress on the wrist and shoulders.

Opposing grip handle: with this design the finger rings are parallel. This is the oldest design and is good for curved shears, because you can use the curved side on both sides without placing extra stress on the body. This type of handle is also good for people who use a wrong cutting technique.

Offset Grip handle: with this design the thumb ring is remarkably shorter than the other finger ring. The finger ring isn’t an extension of the blades, but a bit to the side. This reduces the stress on the hands, but there is a tendency to keep the elbow upwards.

Shank types for dog grooming scissors

The shank of the scissors is a very important factor when buying scissors. The shank is the distance between the fingers and the screw. The length you have to take depends heavily on the length of the fingers and the hand. People with small hands cannot cut with scissors with a too large shank.

The opening of the scissors depends on the length of the shank. If two scissors with shanks of different lengths are placed on top of each other and the same amount is opened at the finger rings, one clearly sees the difference: the scissors with the short shank are more open than those with the big shank.

For a person with long fingers a long shank is good. For a person with short fingers, cutting with a long shank is overloading, because one has to open the fingers too wide. When you scissor a dog, you open and close your scissors about 200 times per minute, about 100 000 per day, so cutting with a too long shank for a long period is very bad for your body and hands. As a professional, it is best to use tailor-fitted scissors. It is good if you can test the scissors in real life.

Screw types for dog grooming scissors

Adjusting the tension of the trimming scissors is very important. It is recommended that the tension of the scissors is adjusted with care and precision, because this has a direct result on the perfect finish of the cutting job. The movement of the scissor blades must be soft and without any force so that the scissor blades can move with a maximum precision and the right technology, thus achieving a perfect end product.

Ordinary screw: This is the original and oldest system and can be adjusted with a screwdriver, or with some scissors a penny. Some groomers prefer this system because the design is nice and smooth, but to adjust the blades you will always need a screwdriver.

Adjustment button: this is an easily adjustable rotary knob (ball).

Leaf-spring tension system: under the adjustment button (ball) is a leaf spring (small plate) that evenly distributes the tension of the scissor blades over the entire length of the scissors.

Ball Bearing Tension adjuster: the spring balance ball bearing stabilizes the shear blades. The different small balls of the bearing are arranged in the center of the scissors and rotate on the bearing instead of a nylon or polemic closing.

Flat Bearing Tension System: a flat bearing tension like a modern screw, but in the middle, there are internal ball bearings. This system is one of the most expensive to make and had a beautiful, smooth look. The tension is adjusted with a custom plate.

Finger ring types for dog grooming scissors

There are different sizes of finger rings for grooming scissors. These can be used by people with small and thin fingers and hands to people with larger and wider hands. If a purchased pair of scissors appears to have too large finger rings, you can use rubber finger rings to make the opening smaller. See Show Tech Finger Ring. These rubbers also help prevent blisters on the fingers.